Comcore's FOCT Introduction

Resources Download

1. FOCT Overview

The pure Fiber Optical Current Transformer (FOCT) is based on the Faraday Effects for measuring electric current in conductor with non-contact method. Its highlight advantage is only a special optical sensing fiber installed at the HV primary point without any other functional components. This tech ensures no high voltage breakdown phenomenon, and greatly improves the reliability of transformers, and far beyond the conventional CT. Therefore, FOCT replacing conventional CT in applications is ultimate trend; meanwhile FOCT will be the representing technology in HV and UHV Smart Grid. As the D&T system operations based on CT feedback information, FOCT is the high-end core equipment in D&T system. As a magnetic field sensor, FOCT is also used in nuclear power, aviation, metallurgy, military and other fields with a wide application prospect.

Comcore FOCT utilize the sensing fiber with their independent developed, and self owned intellectual property rights - special high birefringence optical spun fiber, which has solved the global technical problems - FOCT long-term stability problems; Temperature compensation problems; Small signal noise problems; Anti vibration problems; Sensing ring installation problems (without to disconnect a bus bar or open GIS tank); As well as accuracy problems at 1A rated current in unbalanced current detection between capacitor banks. At the same time, abandoned the traditional hands on process of 1/4 wave plate, greatly improved the scale of producing capacity and consistency of the FOCT performance.

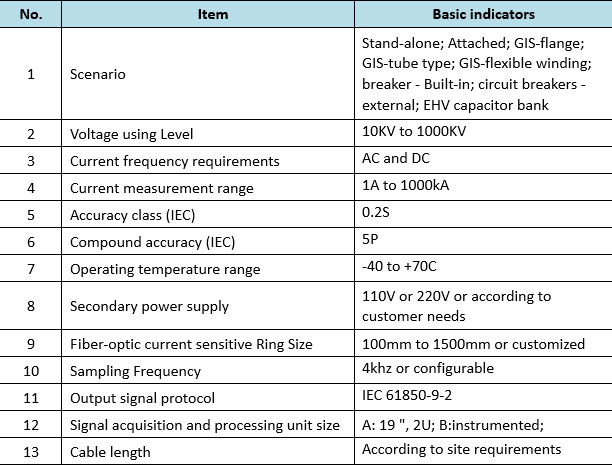

In order to better satisfy applications in electric power industry and other areas, Comcore has developed three categories of FOCTs for different environments and accuracy requests.

Comcore FOCTs

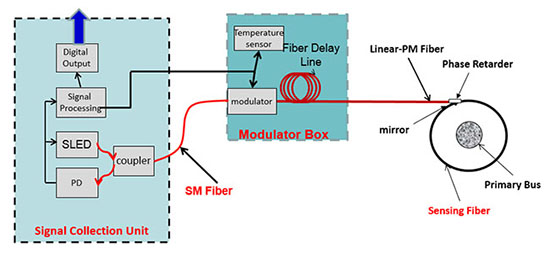

Modulator Unite (MU) is separated from Electric Chassis and connected with single model (SM) fiber in between. Because the SM fiber length can reach as long as 1km, Electric Chassis can be indoor settled in control room as the secondary part, and the sensor head and MU together as the primary part can be installed at the remote measurement point. As the primary part can be processed into foot support style, flexible style, and DIY designed with light, Comcore FOCT TYPE One can be easily installed in harsh electrical environments without disconnected bus bar or GIS equipments.

The prominent feature is the system with Self Correction function to improve the measurement accuracy and MU is integrated inside of the Electrical Chassis. Combined with flexible sensor head, Comcore FOCT can satisfied the high accuracy request applications on aerospace, high tech research, etc.

3. Typical performance of Comcore's FOCT

4. Comcore's FOCT Partially Describes

4.1 Comcore's 220kV FOCT for GIS Application

4.2 Comcore's FOCT for 220kV AIS Application

4.3 Comcore's FOCT for 150kV DC Application

4.4 Comcore's High-Accuracy FOCT for GIS Application

The device has a high-precision current measurement accuracy of 0.05% or less, and does not change with time and temperature. More importantly, the device has a flexible measuring sensitive ring, you can spot around the system, without breaking, easy to install, they can always remove, install, low cost. It also can be used as on-site inspection of the current transformer.

4.5 Comcore's FOCT with flexible sensing cable being tested in SGCC(Wuhan)

4.6 Calibration test for Comcore's FOCT with high-accuracy and high DC in China Institute of Metrology.

Field calibration current from 6000A to 60000A, linearity is better than 0.05%.